Materials

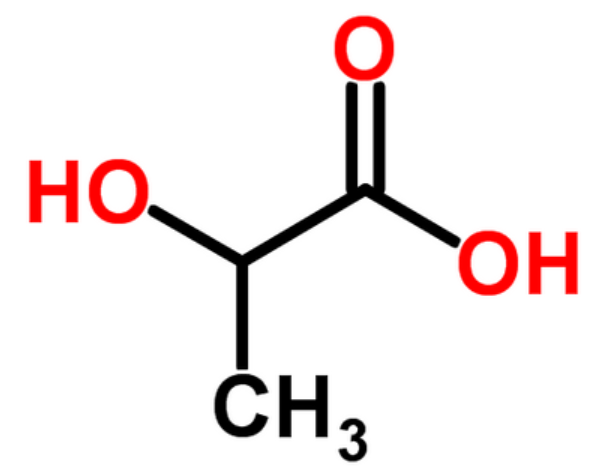

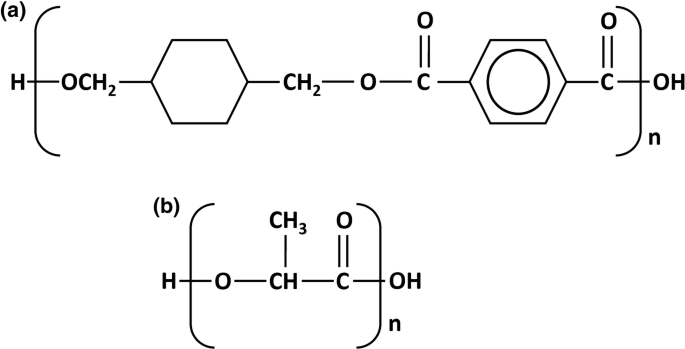

PLA (Polylactic Acid)

PLA (Polylactic Acid) is the most common material used in 3D Printing. This material is an inexpensive material ideal for use in a wide variety of applications. PLA is a, relatively speaking, environmentally friendly 3D printer material that will degrade over time as it is derived from Corn and Sugarcane.

PLA is ideal for inexpensive prototypes, generic model creation, ornaments, gifts, game pieces, toys, and similar.

Pros:

Biodegradable

Very easy to post-process

Material is cheaper than most other materials, on par with ABS

low warping while printing

Cons:

Prints tend to degrade over time due to water or UV exposure

Poor mechanical characteristics compared to other materials

Surfaces can often be rougher than other materials depending on printer resolution

Info:

Tensile Strength: 7250 PSI

Glass Transition Temp: 50-80C

Shore Hardness: 48D-87D

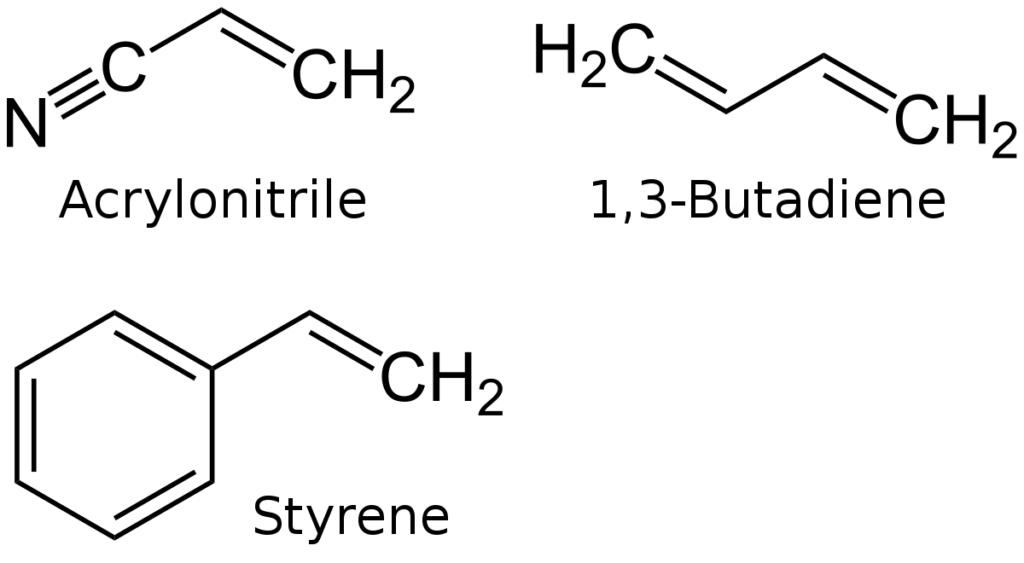

ABS (Acrylonitrile Butadiene Styrene)

ABS (Acrylonitrile Butadiene Styrene) is a hard, impact resistant material that is ideal for parts that need to hold up to extra wear and tear. ABS is commonly seen as the building material for Legos, Game console enclosures, tool handles, and more.

ABS is ideal for low use parts that need higher impact resistance and other uses similar to PLA.

Pros:

High impact resistance

High thermal stability

Very easy to post-process, can achieve a glossy finish with acetone post-processing

Material is cheaper than most other materials, on par with PLA

Cons:

Sli

Parts can warp when printing

Surfaces can often be rougher than other materials depending on printer resolution

Info:

Tensile Strength: 4100 PSI

Glass Transition Temp: 105C

Shore Hardness: 55D-100D

PETG (Polyethylene Terephthalate – Glycol Modifed)

PETG (Polyethylene Terephthalate – Glycol Modifed) is a common material that is often used to make water and drink bottles. PETG is often more chemical resistant than PLA or ABS. The surface of PETG is often softer than that of ABS or PLA, causing it to damage more easily.

PETG is ideal for parts that need to withstand chemicals and works well for parts that will be displayed due to the better surface finish.

Pros:

Glossy finish, smoother, silkier surface

Glycol modification provides higher chemical resistance than PLA or ABS

More UV resistant than PLA

Higher impact resistance than pla

Cons:

Slightly more expensive than PLA

PETG can be Hydroscopic and can be damaged in high heat, high humidity situations

Softer material than PLA

Can be hard to post process due to chemical resistance

Info:

Tensile Strength: 7700 PSI

Glass Transition Temp: 80C

Shore Hardness: ~70D

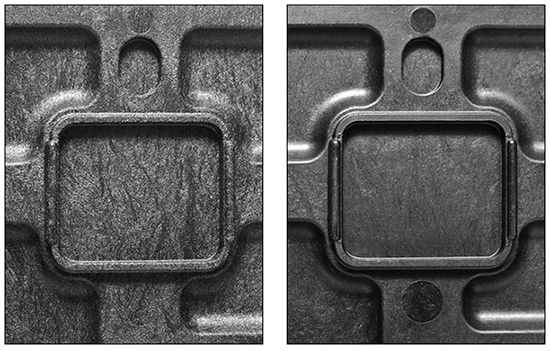

Flexible Filaments

Flexible Filaments are elastic filaments that can bend without breaking. These materials are often a Thermoplastic Elastomer or a form of Rubber. The material flexibility can be between that of a rubber band or as hard as a car tire.

Flexible Filaments are ideal for use in gaskets, boots, seals, joints, cushions, springs, and similar.

M2 Additive is currently refining a method of producing more flexible materials than any other company down to a 35A durometer.

Pros:

Extreme flexibility compared to other materials such as PLA, PETG, or ABS

Offer superior elongation properties, being perfect for Gaskets, Phone Cases, Shock Absorbers, Joint Boots, and more!

Cons:

Low tensile strength

More expensive than PLA or PETG

Very Difficult Post Processing

Surface finish can be sub-par compared to other materials

Info:

Tensile Strength: Varies

Glass Transition Temp: Varies, most near 60C unless otherwise noted

Shore Hardness: 85A-95A or lower

Specialty Filaments

M2 Additive Manufacturing offers a complete line of specialty filaments that do not fit into the above categories. These filaments offer special features such as carbon fiber fill, higher temperatures, or other composites that make them more desirable in certain use cases. We are always experimenting with more materials to add to this list to provide more options to the end use. Check out our instant quote feature to see what specialty filaments we currently have in stock. If your part needs a different specialty filament that is not shown, please contact us and we can see about getting that material in! We also have the ability to use many injection molding materials in our machines, so the options are nearly limitless!

Some of the specialty filaments that we offer are as follows, please feel free to reach out to us for more information on any of these filaments:

Carbon Fiber Filled

Glass Reinforced Nylon

High Temperature PLA

ASA (Acrylonitrile Styrene Acrylate)

And more!

Pros:

ASA is UV stable

Carbon fiber and glass nylons are much stronger than other materials

Others dependent on material

Cons:

More expensive than other filaments

Carbon fiber and glass nylons have rough finish

Others dependent on material

Info:

Tensile Strength: Varies, often 90A+

Glass Transition Temp: Varies, most near 60C unless otherwise noted

Shore Hardness: 80D+

unless otherwise noted

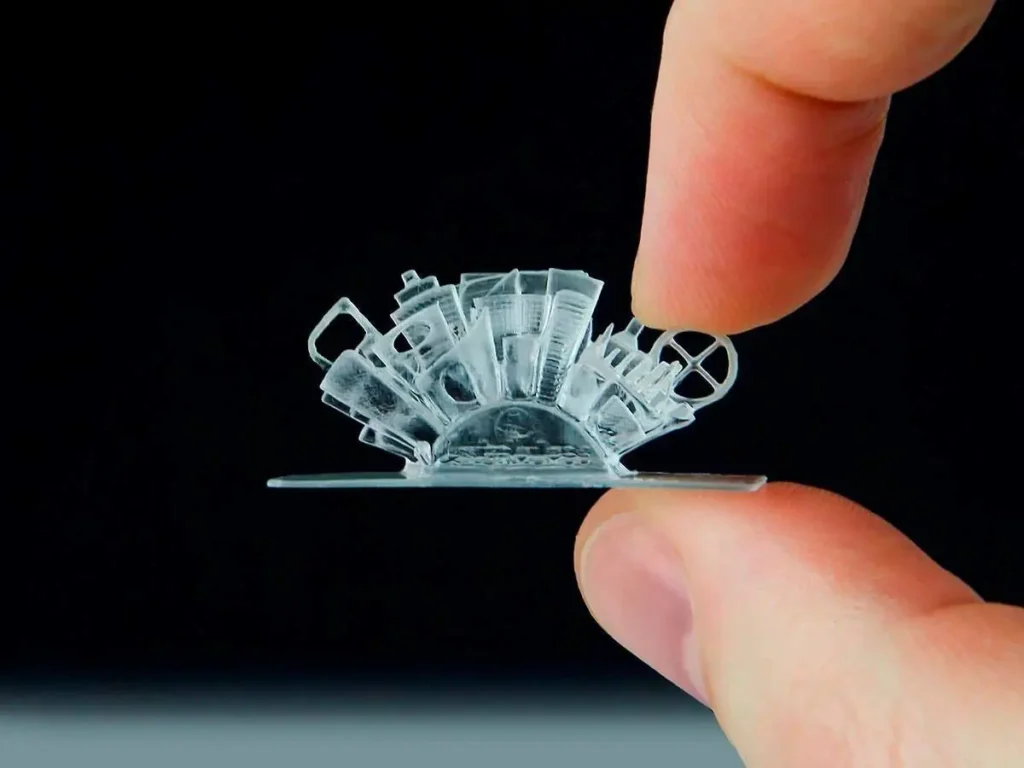

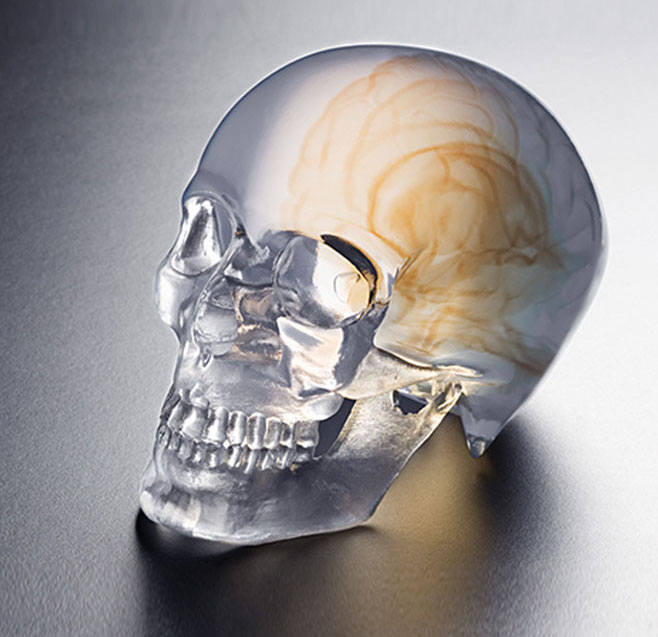

SLA (Stereolithography) Materials

SLA (Stereolithography) Materials

While not currently listed on our instant quote tool due to limitations of the tool, we do offer a full range of Stereolithography capabilities. These prints allow for much high detail and are appropriate for intricate prints or high detail prints that cannot be created using other more traditional methods of manufacturing. Please contact us directly if you would like to get a quote on having parts printed using our Stereolithography Process.

Pros:

Glossy Prints

Stronger Layer Adhesion

Much Higher Detail

Cons:

Often very brittle

Can yellow over time due to UV Exposure

Limited material availability

Info:

Tensile Strength: Varies, often very low, although can be higher

Glass Transition Temp:Varies, often around 50C

Shore Hardness: Varies, often 90A+ although flexible exists

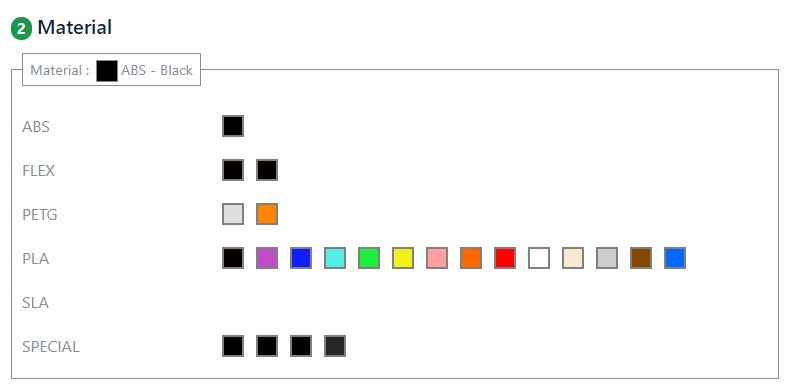

Currently Available Colors

Once you have uploaded a model and selected a process in our instant quote system, located here, you can see the colors we currently have in stock. If there is a specific color that you would like a part created in, but it is not listed, please contact us here and we can look into getting that color in for you!

Example of available colors on the instant quote screen.

Copyright © 2018-2023 M2 Additive Manufacturing LLC